by Larry Beaver, Vice President of Research and Development

There is much misinformation and misunderstanding about low temperature properties of lubricants. Among them is the notion that a low pour point means that an oil can automatically function at very low temperatures. There is much more to understanding low temperature performance than just determining a lubricant’s pour point.

But first, what exactly is a pour point? The ASTM D5950 pour point determination is described as follows:

“This test method covers the determination of pour point of petroleum products by an automatic instrument that tilts the test jar during cooling and detects movement of the surface of the test specimen with an optical device.” (ASTM D5950 Scope 1.1)

ASTM defines the pour point as the lowest temperature at which movement of the fluid is detected using ASTM method D5950. This method does not determine the viscosity of the fluid at the determined pour point temperature, nor does it predict the usability of a lubricant at that temperature. In other words, a low pour point does not guarantee that a lubricant can be used at the pour point temperature (or even near that temperature, for that matter). Of more use is viscosity measured across a temperature range from low to high temperature to give a realistic expectation of the useable temperature range of the product.

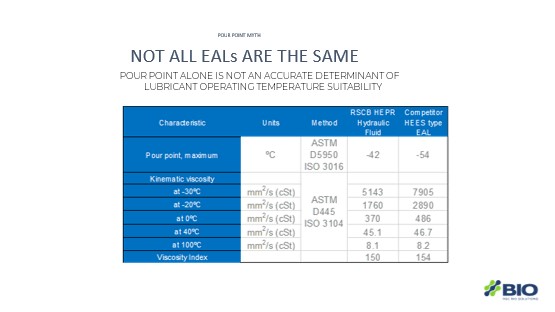

Below is a table showing pour point and viscosity for two ISO 46 hydraulic fluids of similar viscosity index. Note that the fluid that exhibits the lowest pour point, a competitor HEES type EAL, is much higher viscosity (greater than 50% higher) at -30C and -20C than RSC Bio HEPR type EAL at those same temperatures, making the HEES type EAL generally less useful at low temperatures.

This demonstrates that pour point does not tell the complete story when evaluating a lubricant for low temperature applications. Understanding the viscosity-temperature characteristics of the lubricant as well as the anticipated operating conditions, both within the equipment and in the outside environment is critical to selecting the correct fluid for a particular application and operating environment. No single viscosity characteristic tells the whole story. Let our Technical Business Consultants help you sort fact from fiction.