MacGregor RoRo Approvals extend RSC Bio’s comprehensive OEM approval set

June 7, 2022

MacGregor has approved the broad use of RSC Bio’s FUTERRA HF 32 and 46 Hydraulic Fluids ISO viscosities 32 and 46 for all hydraulically driven cargo flow equipment on MacGregor RoRo (Roll On Roll Off) systems.…

Read More

FUTERRA™ ISO 32, 46 hydraulic fluids Achieve Blue Angel Certification

March 16, 2022

FUTERRA™ ISO 32 and 46 viscosity hydraulic fluids are Blue Angel certified.

The Blue Angel is an environmental label in Germany that has been awarded to environmentally friendly products and services since 1978. This certification of FUTERRA™ 32 and FUTERRA™ 46 hydraulic fluids qualify the fluids for consideration in applications such as construction equipment and agricultural uses as well as marine and offshore equipment.

FUTERRA™ hydraulic fluids are produced with fully sustainable, plant-based, synthetic hydrocarbon (HEPR) base oil technology. FUTERRA™ lubricants are also known for their high stability and long lifetimes under the harshest conditions.

Additionally, FUTERRA™ hydraulic fluids also bear the EU Ecolabel certification and are fully US EPA Vessel General Permit compliant EALs (environmentally acceptable lubricants).

Read More

Japan’s Jyunkatsu Net Profiles RSC Bio + Hideki Tominaga

February 15, 2022

(Translated from Japanese)

New Market Development of High-Performance Biodegradable Lubricants based on PAO and related Synthetic Hydrocarbons

Interview with Hideki Tominaga, RSC Bio Solutions

In recent years, awareness of environmental conservation has been increasing around the world, and the United Nations has advocated institutional investors to incorporate the perspective of ESG (environment, society, and governance) into their investments. Therefore, the use of the environmental-friendly type lubricant is expected, such as the adoption and expansion of the biodegradable lubricant which is conscious of the environmental correspondence further in the future.

In the United States, RSC Bio Solutions manufactures and sells biodegradable lubricating oils, gear oils, greases, and cleaning agents towards the world markets. This time, we spoke with Hideki Tominaga, Business Development Manager of the company, about the characteristics of biodegradable lubricants and greases based on the PAO and related Synthetic Hydrocarbons, and the future development in Japan.

History of RSC Bio Solutions

Born in 1924, the Blumenthal family started business with GUNK which has been well-known as a popular automotive engine cleaning agent in Charlotte, North Carolina, USA. In the1980s, RSC Bio Solutions, which manufactures and sells environmentally friendly lubricants and greases, was formed as part of the group company, and we have developed products based on the concept of biobased alternatives to petroleum derived products. After a company acquisition, it has become RSC Bio Solutions, which currently has Blumenthal Holdings as its parent company.

In 2012, environmental regulations in the oceans became stricter and biodegradable lubricants “FUTERRATM”, gear oil, wire rope lubricants and greases ENVIROLOGIC” has been launched. It is characterized by high performance and long-term viscosity and wear resistance under harsh operating conditions. Currently, we manufacture at multiple manufacturing sites in the U.S. and supply it to the world.

Product Features and Application Examples

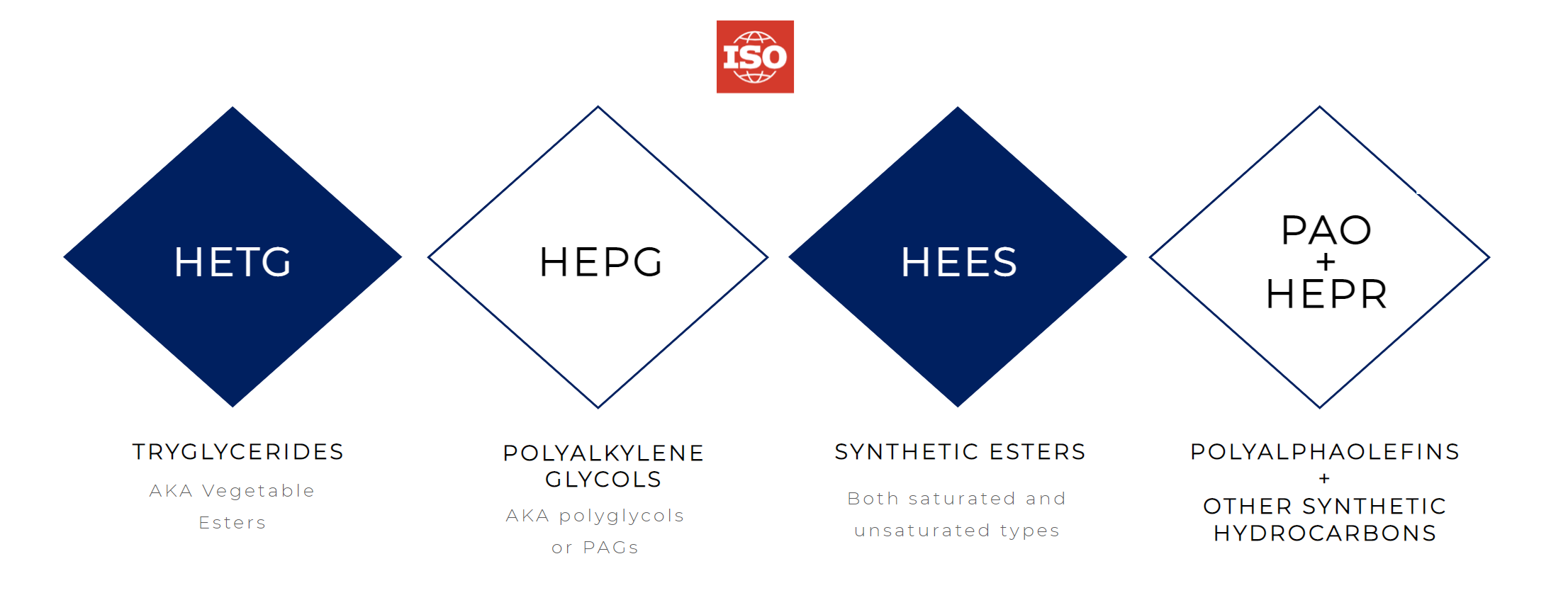

As a feature of our biodegradable lubricants, we have cleared the ISO environmental standard of HEPR, the most stringent performance requirements of the standard, by combining polyalpha olefin (PAO) based on renewable resources and related synthetic hydrocarbon in a well-balanced manner. Specific to the maritime industry, we have been adopted as an environmentally friendly lubricant (EAL) in accordance with the U.S. Environmental Protection Agency (EPA) Ship Entry Regulation (VGP) in 2013. Since the biodegradability test of OECD 301 has been cleared, EAL has high biodegradability, which is less toxic, and has little accumulation in the biological body. All EPA VGP criteria have been cleared. In addition, there are features such as that even if oil leaks, it is not visible (as non-sheening) at sea, and that renewable raw materials are used, pH neutral.

Even if you change from mineral oil-based oil of another company in a place where oil cannot be further used, without replacing the seal – oil change can be done, hydrolysis, compatibility, anti-emulsification is good, and it is hard to emulsify even if seawater enters, there is little foaming, wear resistance better than polyol esters (POS).

FuterraTM series is a high-performance eco-label certified hydraulic oil with excellent oxidation stability and hydrolysis stability and has a long life and good compatibility with sealants due to its foaming characteristics close to zero. It is an important feature.

ENVIROLOGICR GO series is an easy biodegradable synthetic gear oil with excellent system cleanliness characteristics, with no oil film forming and wear resistance and ultra-high-pressure properties, excellent corrosion, and rust protection.

ENVIROLOGICR WREP grease is a water-resistant, ultra-high pressure, and easy biodegradable grease that can be used in water due to its durable adhesive properties and exhibits high performance in corrosive applications where low temperature pressure feed effect, high temperature stability and high load protection are required.

Our products are employed by major shipping companies by obtaining OEM approval for the system components of the world’s leading vessels. We presently supply to 80 countries around the world, mainly in the United States, Europe, and Asia.

In addition to selling products, we also conduct oil analysis of our lubricants in systems free of charge. Our experienced staff provide integrated support with the global organizational sales department and the U.S. headquarters technology department to collaborate with customers and provide improvement proposals.

Domestic Sales and Future Prospects

We are engaged in sales activities directly and with distributors worldwide, but Standard Petroleum Osaka Sales Office (SSOH) became our distributor in Japan from May 2021. SSOH was founded in 1927 as an agent of the Standard Oil Company of New York Japan and has a long track record of selling lubricants to marine and industrial customers. SSOH is well equipped to assist marine and industrial customers in making the transition to unique, high performance, renewable based lubricants.

In the future, we will expand markets served in Japan to include the offshore field, heavy machinery and workboats in port construction, offshore wind power generation, mainly for ships with a high track record of adoption so far, I would like to put a great effort into the future. – Thank you very much.

Read More

Pile Buck + Dr. Larry Beaver on Why Futerra is a Better EAL Option

February 1, 2022

FUTERRA™ lubricants offered by RSC Bio Solutions are unique in both their stability and performance. FUTERRA is offered in a wide range of viscosities from ISO 15 all the way up to ISO 150. Applications include hydraulic systems and stern tubes. But why choose a FUTERRA™ fluid for these applications over a conventional lubricant or a competitive environmentally acceptable lubricant (EAL)?

Read More

Choosing the Right Lubricant for Civil Works Projects

January 24, 2022

A helpful primer on lubricant selection for civil works projects – especially those on and near waterways.

Read More