VEROPE Approves ENVIROLOGIC Greases Extending RSC Bio’s Comprehensive OEM Approval Set

July 12, 2022

VEROPE® AG has approved the use of RSC Bio EnviroLogic® greases for in-service relubrication of veropes special wire ropes utilized in global shipping, port, offshore, mining, construction and heavy industries.

EnviroLogic WREP Grease NLGI grades 0 and 2: Water Resistant, Extreme Pressure greases are biodegradable, PAO and related base oil class with high resistance to water wash out, extreme pressure performance, broad operating temperature range, oxidation stability and good pumpability specifically developed for high load performance requirements such as wire rope applications across shipping, port, offshore, mining, construction, and heavy industries.

The primary reasons for approving Environmentally Acceptable Lubricants (EALs) such as EnviroLogic WREP greases are:

The technical performance characteristics of EnviroLogic WREP Greases are best-in-class.

EnviroLogic® WREP greases were specifically developed for marine and outdoor lubricant applications. Made with PAO and related hydrocarbon base oils, these greases are designed to provide a no-compromise option for high performance applications that require the grease to remain in place – even under water. These greases have a high level of performance in corrosive applications that demand durable adhesive characteristics, low temperature pumpability and high temperature stability and high load protection.

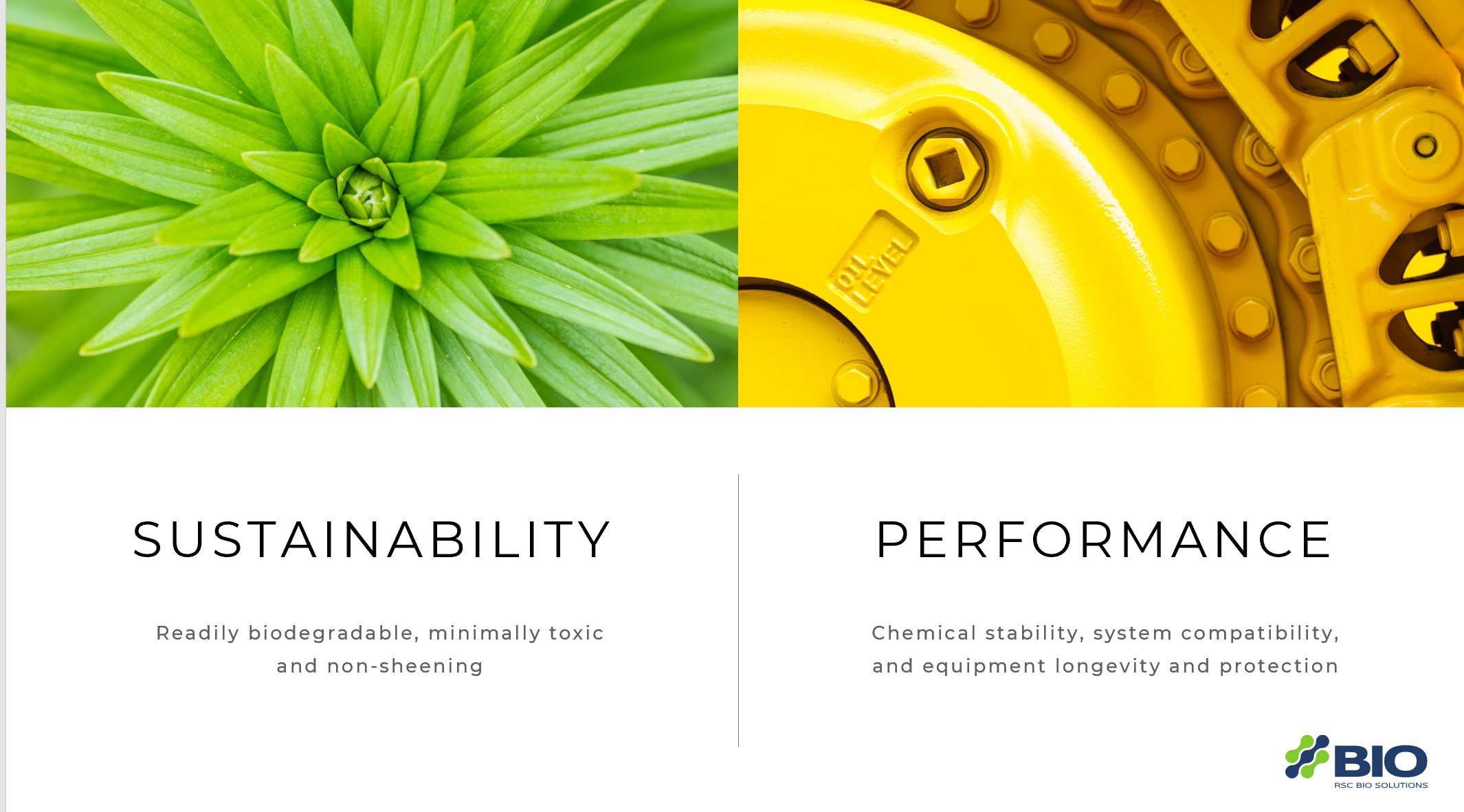

EnviroLogic WREP Greases are readily biodegradable, minimally toxic to aquatic life and animals and are Environmentally Acceptable Lubricants (EALs) compliant with the 2013 US EPA Vessel General Permit (VGP).

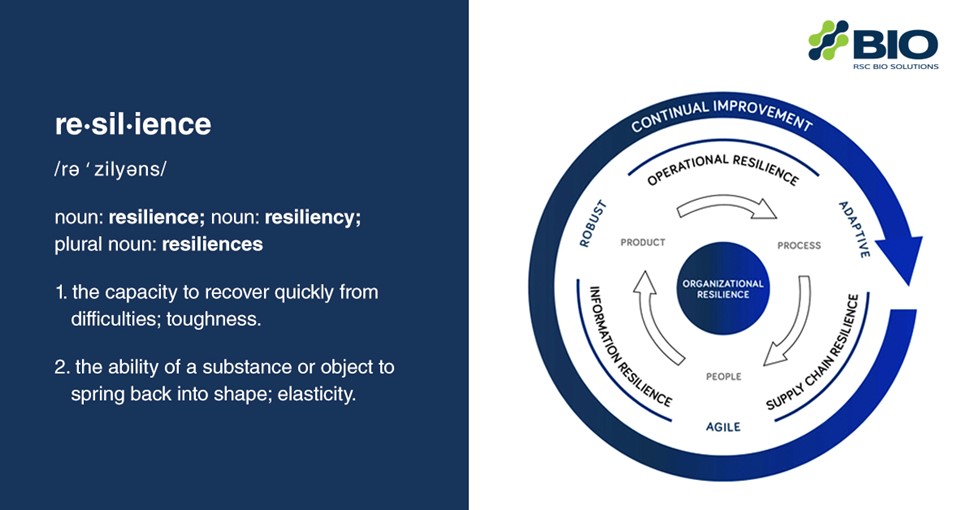

Post Pandemic Trends – Resiliency – by Mike Guggenheimer

June 9, 2022

As most of the world emerges from Covid-related travel restrictions, I have been able to spend more time face-to-face with customers and other leaders. It strikes me how different the conversations are after these last two challenging years. For RSC Bio Solutions, interest in and use of our technologies have been largely driven by environmental and operational risk mitigation. Specifically, incidental discharge of spills and leaks by marine vessels or mobile equipment operating in and around water or sensitive environments that can negatively impact the operator’s brand, expose the company to risk of fines, and cause downtime and costly remediation.

This particular concern still exists. In fact, it is increasing. But there are new challenges growing in importance stemming from the unprecedented business and economic disruptions caused by the COVID pandemic, COVID-related supply chains issues, and geopolitical instabilities providing a new perspective on this risk. With risk, comes opportunities for leaders to differentiate.

The more immediate impact of the disruptions of the last few years is an increased focus on sustainability as a key business strategy to reduce supply chain and operational risks. In this view, resiliency is the desired outcome of a wholistic view of sustainability. The partners we work with and the leaders I have been speaking with lately are looking at developing a supply base and sourcing strategy designed to minimize potential downtime, delays and shortages. Sustainable technology, through this lens, can mean solutions that are less dependent on petroleum price volatility, ones that reduce the risk of downtime, or options that have broader applicability and compatibility with existing systems, regulations, and stakeholder requirements. We can expect additional disruptions and shocks to the system, but the last two years have exposed the need to develop operational strategies that allow for a quick recovery.

RSC Bio has been at the forefront of high performance, more sustainable technology development for nearly 40 years. With best-in-class performance and extensive OEM approvals for a wide range of environmentally acceptable solutions, we increasingly find ourselves acting as a guide, working with fleet operators to explore how green technologies can be part of a broader resiliency strategy. Now more than ever, these explorations are centered on developing a roadmap that anticipates the next disruption rather than hoping for the best.

MacGregor RoRo Approvals extend RSC Bio’s comprehensive OEM approval set

June 7, 2022

MacGregor has approved the broad use of RSC Bio’s FUTERRA HF 32 and 46 Hydraulic Fluids ISO viscosities 32 and 46 for all hydraulically driven cargo flow equipment on MacGregor RoRo (Roll On Roll Off) systems.

The primary reasons for approving Environmentally Acceptable Hydraulic Fluid Lubricants (EALs) from RSC Bio based on renewable resource based PAO and other synthetic hydrocarbon technologies are:

In addition to field proven performance, these products are US EPA VGP compliant, EU Ecolabel certified, and German Blue Angel listed.

There are no required design or material changes to cargo flow equipment because RSC Bio HEPR technology is broadly compatible with seal materials – most especially NBR type which is used extensively in MacGregor systems already. This facilitates changeover from non-environmental to environmental type lubricants more broadly as vessels seek ways to meet decarbonization goals and mandates.

FUTERRA hydraulic fluid longevity and stability meet or exceed MacGregor expected service interval requirements for RoRo systems (fill and forget).

FUTERRA HF 32 and 46 are drop in replacements for mineral oil, vegetable and synthetic ester based oils. As cargo flow systems are complex, this can greatly reduce the number of drain, flush and fill service cycles required to convert RoRo systems to EALs – saving labor and time.

FUTERRA 32 and 46 provide peace of mind in the event of a hydraulic system leak. On board, many hydraulic fluids can damage high value cargo – especially automotive cargo as FUTERRA is compatible with automotive car paint. Incidental discharges of environmentally acceptable lubricants are generally dealt with by maritime authorities less severely than discharges of conventional hydraulic fluids which sheen and negatively impact aquatic life.

MacGregor has also approved the use of ENVIROLOGIC 2 WREP water resistant, extreme pressure lithium complex grease for lubrication of their RoRo dynamic systems. With it’s best-in-class performance and environmental profile, this lithium complex formulation is ideal for use as a multipurpose grease in marine environments.

Sea Japan video retrospective

April 25, 2022

Read More

Happy Earth Day!

April 21, 2022

Happy Earth Day! RSC Bio’s lubricant technologies offer the performance Global Marine Operators need, while minimizing environmental exposure concerns. The best of both worlds. Because there is no PLANet B.

What’s a Pour Point? Is it Important?

March 23, 2022

by Larry Beaver, Vice President of Research and Development

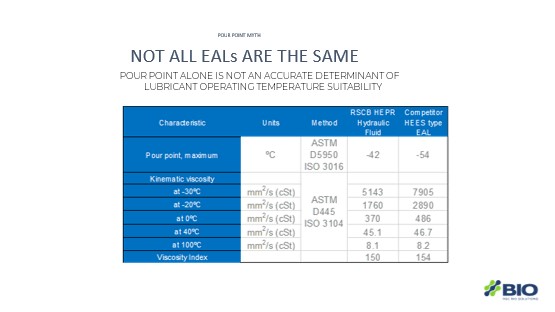

There is much misinformation and misunderstanding about low temperature properties of lubricants. Among them is the notion that a low pour point means that an oil can automatically function at very low temperatures. There is much more to understanding low temperature performance than just determining a lubricant’s pour point.

But first, what exactly is a pour point? The ASTM D5950 pour point determination is described as follows:

“This test method covers the determination of pour point of petroleum products by an automatic instrument that tilts the test jar during cooling and detects movement of the surface of the test specimen with an optical device.” (ASTM D5950 Scope 1.1)

ASTM defines the pour point as the lowest temperature at which movement of the fluid is detected using ASTM method D5950. This method does not determine the viscosity of the fluid at the determined pour point temperature, nor does it predict the usability of a lubricant at that temperature. In other words, a low pour point does not guarantee that a lubricant can be used at the pour point temperature (or even near that temperature, for that matter). Of more use is viscosity measured across a temperature range from low to high temperature to give a realistic expectation of the useable temperature range of the product.

Below is a table showing pour point and viscosity for two ISO 46 hydraulic fluids of similar viscosity index. Note that the fluid that exhibits the lowest pour point, a competitor HEES type EAL, is much higher viscosity (greater than 50% higher) at -30C and -20C than RSC Bio HEPR type EAL at those same temperatures, making the HEES type EAL generally less useful at low temperatures.

This demonstrates that pour point does not tell the complete story when evaluating a lubricant for low temperature applications. Understanding the viscosity-temperature characteristics of the lubricant as well as the anticipated operating conditions, both within the equipment and in the outside environment is critical to selecting the correct fluid for a particular application and operating environment. No single viscosity characteristic tells the whole story. Let our Technical Business Consultants help you sort fact from fiction.

FUTERRA™ ISO 32, 46 hydraulic fluids Achieve Blue Angel Certification

March 16, 2022

FUTERRA™ ISO 32 and 46 viscosity hydraulic fluids are Blue Angel certified.

The Blue Angel is an environmental label in Germany that has been awarded to environmentally friendly products and services since 1978. This certification of FUTERRA™ 32 and FUTERRA™ 46 hydraulic fluids qualify the fluids for consideration in applications such as construction equipment and agricultural uses as well as marine and offshore equipment.

FUTERRA™ hydraulic fluids are produced with fully sustainable, plant-based, synthetic hydrocarbon (HEPR) base oil technology. FUTERRA™ lubricants are also known for their high stability and long lifetimes under the harshest conditions.

Additionally, FUTERRA™ hydraulic fluids also bear the EU Ecolabel certification and are fully US EPA Vessel General Permit compliant EALs (environmentally acceptable lubricants).

Read More

Is Lithium for Grease Formulations in Short Supply?

March 8, 2022

by Doug Adams, Senior Development Chemist

RSC Bio Solutions is a green technology company that manufactures Environmentally Acceptable Lubricants (EALs) and I am proud that the greases I develop are Vessel General Permit (VGP) compliant and perform the same or better than the greases in their category.

When tasked to develop these greases in 2016, there was a significant amount of literature reporting shortages of Lithium. The shortage of Lithium was said to be based upon the growth in the use of Lithium in the Electric Vehicle (EV) batteries.

It is now 2022, and the Lithium Complex greases developed in 2016 have been manufactured on time and the predicted shortages of Lithium have yet to materialize. The reasons that significant shortages of Lithium did not occur include:

- There are Lithium deposits in Mexico, Canada, Australia, South America, Africa, Europe as well as the United States.

- Lithium can be sourced from clay, brine or it can mined (Spodumene).

- The facilities that mine and refine Lithium ramped up production in anticipation of the increased demand.

- More than half of EV batteries and other storage batteries are recycled.

Battery technology for solar panels and for EV will continue to evolve and there is a distinct possibility that lithium in these rechargeable batteries may change.

Lithium-ion batteries account for nearly 75% of current lithium use while the lubricants market accounts for only 3% of lithium demand. Consequently, for the next 15-20 years, lithium should continue to be readily available to make lithium-based greases. Moving away from lithium-based greases when this technology is extremely effective, cost efficient and readily available does not appear to be necessary.

So, there should be no need to adopt inferior grease technologies out of a fear that lithium demand will outpace supply.

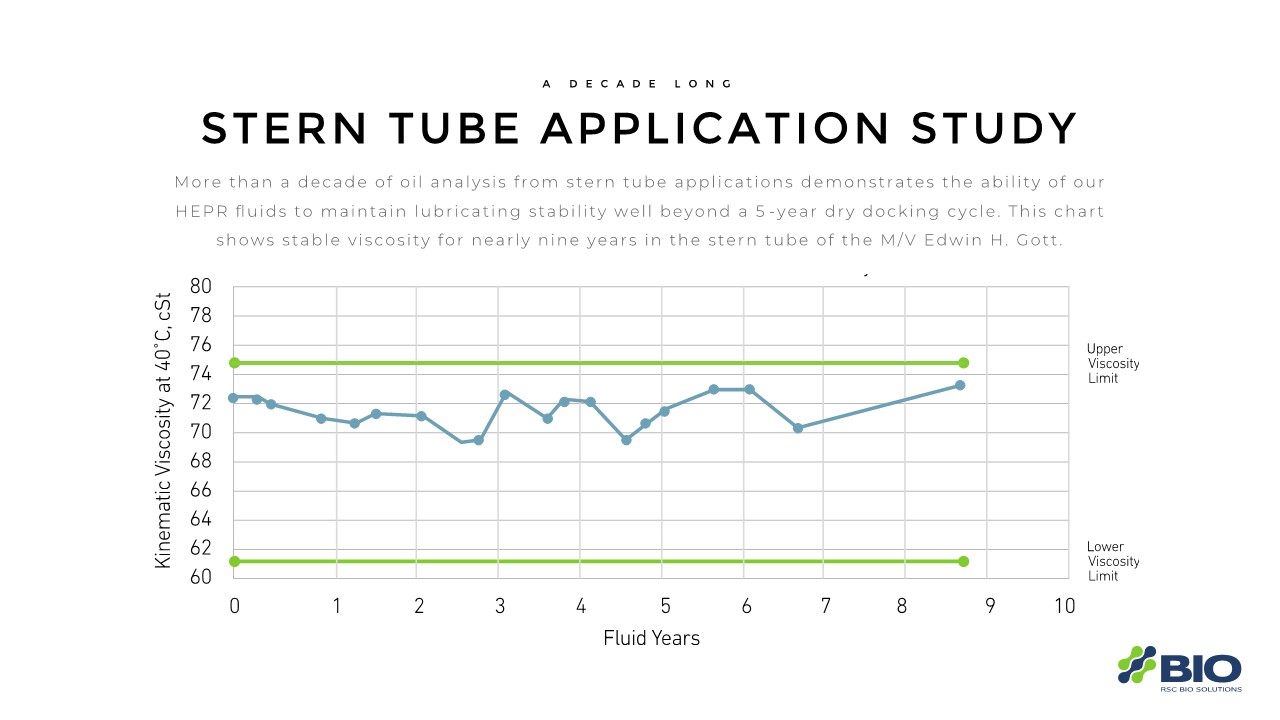

EAL Longevity and Why it Matters

February 28, 2022

RSC Bio Environmentally Acceptable HEPR type Lubricants maintain lubricating stability well beyond a five-year dry docking cycle. Our ENVIROLOGIC and FUTERRA EALs regularly meet and or exceed performance requirements of the most demanding applications including stern tube and gear oils. Not all four types of EALs can demonstrate the lubricating stability that our best-in-class lubricants can. Here’s one of many oil analyses measuring the kinematic viscosity of RSC Bio’s HEPR lubricant in every day use in a stern tube application.

A typical deep water vessel dry dock cycle is five years. In this example, it’s been nine plus years since the stern tubes of the M/V Edwin H. Gott were filled with EnviroLogic HEPR type EAL and the oil is still in spec. This is because RSC Bio’s environmentally acceptable lubricants are engineered for hydrolytic and oxidative stability. EALs are the only type of lubricants we offer. Let us help you decipher the differences among EALs and conventional lubricants alike, test criteria and why it all matters.

What’s a Drop-In Replacement?

February 23, 2022

OUR CUSTOMERS DEFINE DROP-IN REPLACEMENT AS… “Replacement of their existing lubricant with RSC Bio HEPR type EALs with minimal flush-out and no substantive changes to hardware such as seals, gaskets, etc. required to successfully use HEPR EALs for at least one dry dock cycle. There is no negative impact on performance or lifetime of seals, gaskets, etc. following changeover.”

Contact us to learn more about key lubricant characteristics and test methods which can predict and measure lubricant performance in systems as well as why RSC Bio lubricants are best in class.

Japan’s Jyunkatsu Net Profiles RSC Bio + Hideki Tominaga

February 15, 2022

(Translated from Japanese)

New Market Development of High-Performance Biodegradable Lubricants based on PAO and related Synthetic Hydrocarbons

Interview with Hideki Tominaga, RSC Bio Solutions

In recent years, awareness of environmental conservation has been increasing around the world, and the United Nations has advocated institutional investors to incorporate the perspective of ESG (environment, society, and governance) into their investments. Therefore, the use of the environmental-friendly type lubricant is expected, such as the adoption and expansion of the biodegradable lubricant which is conscious of the environmental correspondence further in the future.

In the United States, RSC Bio Solutions manufactures and sells biodegradable lubricating oils, gear oils, greases, and cleaning agents towards the world markets. This time, we spoke with Hideki Tominaga, Business Development Manager of the company, about the characteristics of biodegradable lubricants and greases based on the PAO and related Synthetic Hydrocarbons, and the future development in Japan.

History of RSC Bio Solutions

Born in 1924, the Blumenthal family started business with GUNK which has been well-known as a popular automotive engine cleaning agent in Charlotte, North Carolina, USA. In the1980s, RSC Bio Solutions, which manufactures and sells environmentally friendly lubricants and greases, was formed as part of the group company, and we have developed products based on the concept of biobased alternatives to petroleum derived products. After a company acquisition, it has become RSC Bio Solutions, which currently has Blumenthal Holdings as its parent company.

In 2012, environmental regulations in the oceans became stricter and biodegradable lubricants “FUTERRATM”, gear oil, wire rope lubricants and greases ENVIROLOGIC” has been launched. It is characterized by high performance and long-term viscosity and wear resistance under harsh operating conditions. Currently, we manufacture at multiple manufacturing sites in the U.S. and supply it to the world.

Product Features and Application Examples

As a feature of our biodegradable lubricants, we have cleared the ISO environmental standard of HEPR, the most stringent performance requirements of the standard, by combining polyalpha olefin (PAO) based on renewable resources and related synthetic hydrocarbon in a well-balanced manner. Specific to the maritime industry, we have been adopted as an environmentally friendly lubricant (EAL) in accordance with the U.S. Environmental Protection Agency (EPA) Ship Entry Regulation (VGP) in 2013. Since the biodegradability test of OECD 301 has been cleared, EAL has high biodegradability, which is less toxic, and has little accumulation in the biological body. All EPA VGP criteria have been cleared. In addition, there are features such as that even if oil leaks, it is not visible (as non-sheening) at sea, and that renewable raw materials are used, pH neutral.

Even if you change from mineral oil-based oil of another company in a place where oil cannot be further used, without replacing the seal – oil change can be done, hydrolysis, compatibility, anti-emulsification is good, and it is hard to emulsify even if seawater enters, there is little foaming, wear resistance better than polyol esters (POS).

FuterraTM series is a high-performance eco-label certified hydraulic oil with excellent oxidation stability and hydrolysis stability and has a long life and good compatibility with sealants due to its foaming characteristics close to zero. It is an important feature.

ENVIROLOGICR GO series is an easy biodegradable synthetic gear oil with excellent system cleanliness characteristics, with no oil film forming and wear resistance and ultra-high-pressure properties, excellent corrosion, and rust protection.

ENVIROLOGICR WREP grease is a water-resistant, ultra-high pressure, and easy biodegradable grease that can be used in water due to its durable adhesive properties and exhibits high performance in corrosive applications where low temperature pressure feed effect, high temperature stability and high load protection are required.

Our products are employed by major shipping companies by obtaining OEM approval for the system components of the world’s leading vessels. We presently supply to 80 countries around the world, mainly in the United States, Europe, and Asia.

In addition to selling products, we also conduct oil analysis of our lubricants in systems free of charge. Our experienced staff provide integrated support with the global organizational sales department and the U.S. headquarters technology department to collaborate with customers and provide improvement proposals.

Domestic Sales and Future Prospects

We are engaged in sales activities directly and with distributors worldwide, but Standard Petroleum Osaka Sales Office (SSOH) became our distributor in Japan from May 2021. SSOH was founded in 1927 as an agent of the Standard Oil Company of New York Japan and has a long track record of selling lubricants to marine and industrial customers. SSOH is well equipped to assist marine and industrial customers in making the transition to unique, high performance, renewable based lubricants.

In the future, we will expand markets served in Japan to include the offshore field, heavy machinery and workboats in port construction, offshore wind power generation, mainly for ships with a high track record of adoption so far, I would like to put a great effort into the future. – Thank you very much.

Read More

Pile Buck + Dr. Larry Beaver on Why Futerra is a Better EAL Option

February 1, 2022

FUTERRA™ lubricants offered by RSC Bio Solutions are unique in both their stability and performance. FUTERRA is offered in a wide range of viscosities from ISO 15 all the way up to ISO 150. Applications include hydraulic systems and stern tubes. But why choose a FUTERRA™ fluid for these applications over a conventional lubricant or a competitive environmentally acceptable lubricant (EAL)?

Read More

Choosing the Right Lubricant for Civil Works Projects

January 24, 2022

A helpful primer on lubricant selection for civil works projects – especially those on and near waterways.

Read More

Dr. Larry Beaver on WHY FUTERRA™ IS A BETTER HYDRAULIC FLUID FOR LAND & MARINE APPLICATIONS

January 18, 2022

The FUTERRA™ lubricants offered by RSC Bio Solutions are unique in both their stability and performance. FUTERRA is offered in a wide range of viscosities from ISO 15 all the way up to ISO 150. Applications include hydraulic systems and stern tubes. But why choose a FUTERRA™ fluid for these applications over a conventional lubricant or a competitive environmentally acceptable lubricant (EAL)? FUTERRA hydraulic fluids offer the performance properties and stability associated with a premium mineral oil-based lube while exceeding the stability of most mineral oils and all competing EALs. In fact, FUTERRA™ performs well under the harshest operating conditions and has the added benefit of EAL VGP-compliance.

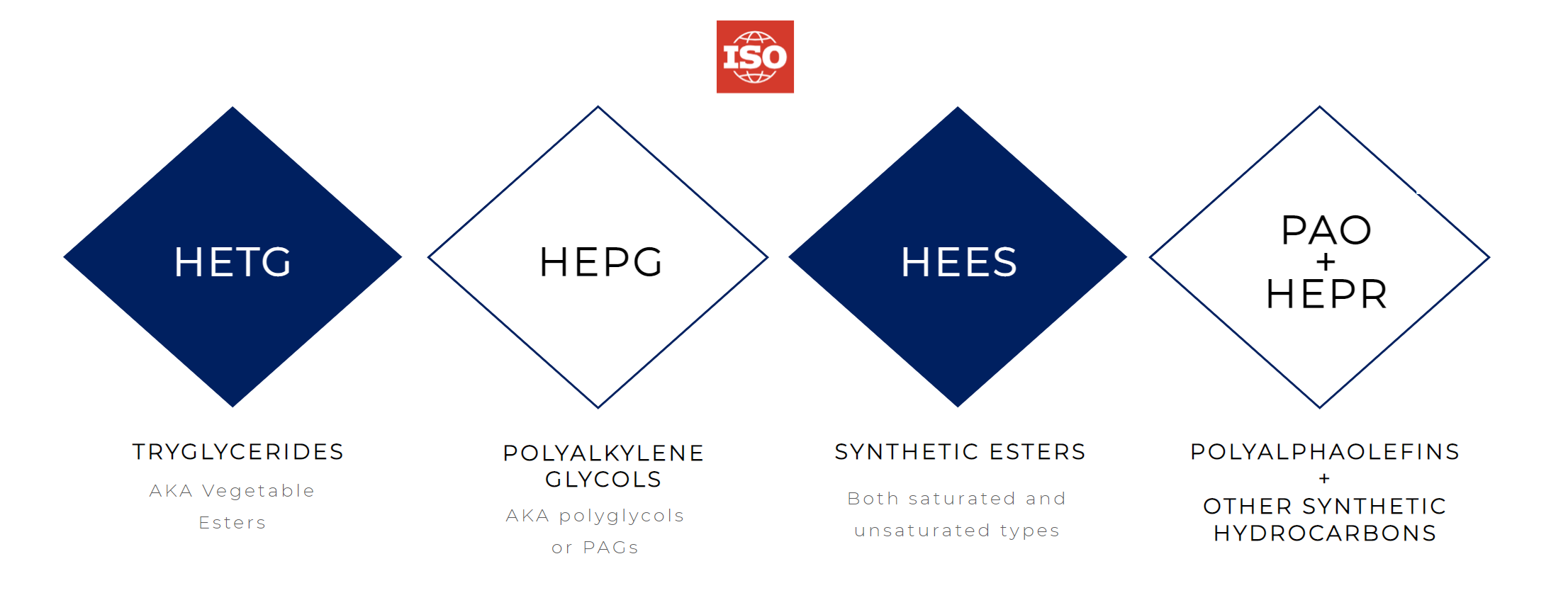

FUTERRA lubricants meet the strict standards set for HEPR hydraulic fluids as outlined in the ISO 15380 standard that codifies the performance requirements for environmentally acceptable hydraulic fluids that are manufactured using polyalphaolefin (PAO) or related base oils. The other three ISO categories of fluid are HETG (triglyceride), HEPG (poly glycols) and HEES (synthetic esters).

The primary competitors to RSV Bio’s FUTERRA series are products made with synthetic esters (HEES). A review of the ISO 15380 standard reveals the minimum stability and performance requirements outlined for the high-performance HEPR category of fluid as well as the requirements for the EALs using the other base oil types. The HEES-type fluids have lower stability requirements set by ISO 15380 because synthetic ester base oils are inherently less stable than HEPR fluids and chemically degrade in the presence of the moisture that they invariably encounter during use in both marine and land-based applications.

Beware of “apples to oranges” comparisons by HEES (synthetic ester) competitors touting comparable stability using modified tests that artificially enhance hydrolytic and oxidative stability test results. For example, HEPR fluids must reach at least 1000 hours of oxidative stability in the ISO 4263-1 “wet TOST” test referenced in ISO 15380, while the HEES fluids must only record their results in a modified version of the same test where water that would normally be in the test is not included. This of course “stacks the deck” and makes esters look comparable in the test when in fact they perform poorly in real-world applications where moisture or water is the common contaminant.

It is very important to understand test specifics and results prior to making lubricant selection decisions for your equipment. FUTERRA fluids are best-in-class and are the best choice because FUTERRA is engineered for stability, performance, and environmental compliance.

Feel free to contact RSC Bio technical experts directly for information on the requirements for the ISO 15380 standard as well regulations and certifications that pertain to the use of EALs.

Pile Buck Interview with RSC Bio on EALs

January 12, 2022

A five minute primer on the what, why and when of EALs.

Read More

Not All EALs Are the Same

January 10, 2022

According to the international ISO Standard, there are four different types of environmental hydraulic fluids (also known as EALs / Environmentally Acceptable Lubricants defined by US EPA 2013 VGP). Each type varies significantly in hydrolytic and oxidative stability with PAO + HEPR type being most durable and stable – inherently.

RSCB’s EnviroLogic HF HP and Futerra HF series lubricants are based on synthetic and renewable PAO + HEPR, respectively. To understand the significant performance and durability differences in Synthetic Ester EALs and Best-in-Class PAO + HEPR EALs from RSC Bio, access our webinar at your convenience to understand the true differences in these technologies.

Read More

Japan’s Kaiji Press features RSC Bio Solutions and Hideki Tominaga

December 8, 2021

RSC Bio News at Kaiji Press_Edit120221 final

RSC Bio and SSOH Team in Japan to Offer Best in Class EALs

December 6, 2021

INDIAN TRAIL, NC, USA (December 6, 2021) – To meet the growing demand for Environmentally Acceptable Lubricant (EAL) offerings in Japan for marine and industrial applications, RSC Bio Solutions and Standard Sekiyu Osaka Hatsubaisho Co., Ltd (SSOH) are excited to announce a new distribution partnership.

“We are proud to be playing a leadership role in developing innovative solutions to address the accelerating environmental and performance challenges heavy equipment and maritime operators face today,” said Mike Guggenheimer, President and CEO of RSC Bio Solutions. “As we respond to growing demand, we are expanding our team in key markets such as Japan with SSOH, a leading company name with a 95 year plus established brand, reputation, and reliability with knowledgeable sales and technical resources and established business networks in marine, industrial and automotive industries.”

As noted by Shigehisa Yura, General Manager, Corporate Planning for SSOH, “We expect the EAL demand in Japan will grow in accordance with the expansion of environmental awareness in the marine and industrial segments. In addition to increasing EAL demand, there is a growing need for high performance lubricants which can contribute to Japanese customers’ challenges on an overall lower total cost of ownership. SSOH’s aim is to add superior products with differentiated longevity and performance features from other EAL and non EAL type lubricants commonly on offer.”

As part of its overall expansion effort, RSC Bio Solutions is significantly increasing its distribution and supply chain coverage in EMEA and APAC. The business had relied on a single global marine distribution and sales partner but recently shifted its strategy to team with strong regional distributor partners such as SSOH, increase its own stock levels in key hubs, and dramatically advance its overall technical support capabilities direct with end users to better meet the accelerating demand.

“Over nearly four (4) decades of experience delivering PAO and synthetic hydrocarbon related technologies, we have developed a reputation for technical and product expertise,” said Mr. Guggenheimer. “We have found a sweet spot between ensuring we have extremely high levels of technical and delivery service while maintaining partnerships and direct connection with the users of our technology. Our end users are increasingly relying on RSC Bio Solutions personnel and partners to develop strategic roadmaps to mitigate risk and plan for a future where sustainability is no longer optional.”

About RSC Bio Solutions

RSC Bio Solutions is a portfolio company of Blumenthal Holdings and a global leader in sustainable technology for marine and industrial markets with four decades of experience in the most demanding applications. The company is committed to helping global operators reduce environmental risk, increase uptime, and chart a path to a more sustainable future with technologies that rival the performance and compatibility of the best petroleum-based products. For more information visit our website www.rscbio.com or to learn more about our latest project to help businesses keep employees and customer safer, visit www.clean-safely.com.

About Standard Sekiyu Osaka Hatsubaisho Co., Ltd

Standard Sekiyu Osaka Hatsubaisho Co., Ltd (SSOH) was founded in 1927 as an agent of Japan Branch of Standard Oil Company of New York (Socony) to market Pegasus branded fuel and lubricants first in Japan. Since the establishment, SSOH has been focusing on the stable supply of superior petroleum based and diversified products through safe business operations and corporate compliance, making sure that building trust with stake holders is the priority of all business processes and activities under the company creed “Honesty” with a saying “Harmony is to be valued”.

RSC Bio Solutions Featured by Pile Buck

November 11, 2021

Read Pile Buck’s interview with RSC Bio Solutions, a leader in high-performing Environmentally Acceptable Lubricants (EALs) including hydraulic fluids, gear oils, and water-resistant greases for marine and land applications.

Read More

Why EALs (in Three Minutes) with Dr. Larry Beaver

November 1, 2021

Read More

RSC Bio Included in Marine News MN 100

October 14, 2021

RSC BIO SOLUTIONS is excited to share its inclusion in Marine News 2021 MN 100 List as a leading company serving the North American shallow draft market (Workboat | Offshore| Inland Marine| Coastal Marine). Thanks to Editor, Eric Haun and the Marine Link team for recognizing our company!

Read More

RSC Bio’s Doug Adams on possibilities for re-refining engine oil

July 15, 2021

Reprinted TLT August 21 Feature with permission

Re-refining and chemical recycling processes can turn used oil and plastic waste into usable products.

There are two broad approaches to motor oil recycling: re-refining and chemical recycling.

- Re-refining aims to extend the fluid’s utility for another generation and avoid releasing it as a pollutant into the environment.

- Chemical recycling breaks down plastic waste into smaller components to be used as base oils in new products.

Refining crude oil for industrial use relies on separation processes like centrifuging and distillation to remove impurities and separate small and large hydrocarbons for use in different applications. In order to turn used oil into desirable products, plants can use similar approaches to those applied to crude oil to remove unwanted particles and sort degraded hydrocarbons from usable ones.

There are two broad approaches to motor oil recycling: re-refining and chemical recycling. Re-refining aims to extend the fluid’s utility for another generation and avoid releasing it as a pollutant into the environment, while chemical recycling starts with breaking down the hydrocarbons that gave the former oil its unique properties in order to create feedstock for a wide variety of new products. Both approaches start with removing contaminants like dirt and metal particles from the fluid. Acid treatments trap greases and gums suspended in the fluid, while separation techniques like sedimentation, filtration and decantation remove them later, along with heavier sediments and metals. Chemical recycling then goes even further to return value to the used lubricant by breaking down the hydrocarbons into simple feedstocks that can then be used as components of other products.

Large recycling services tend to focus on the spent hydrocarbon streams that produce the greatest volume of recyclable materials, partly in order to secure a place in the broader petrochemical value chain. Scott Miller, senior vice president of refinery operations at Safety-Kleen, says the company collects some 200 million gallons of used motor oil per year in the U.S. and Canada. “[Recycled] oil’s quality is directly linked to the quality of used motor oils which are collected,” explains Miller. “As OEMs have continued to progress their lubricant quality requirements, today’s engine oils begin with a minimum quality level of Group II, which increases up to Group III and PAOs.”

Each re-refining process adds a layer of complexity to the already intricate role of base oils in industrial use, making the precise environmental impact of a particular final product even more difficult to ascertain. Re-refined base oils inherently don’t qualify as environmentally acceptable lubricants (EALs), though they do have the benefit of reducing the volume of used-oil waste that returns to the earth. STLE member Douglas J. Adams, senior product development chemist at RSC Bio Solutions, says the requirements for each designation of EAL are sharply defined by the Vessel Incidental Discharge Act (VIDA), formerly the Vessel General Permit (VGP), based on their base oil types.

Base fluids that are prescribed for use in EALs are triglycerides, synthetic esters, polyalkylene glycols and PAO and related hydrocarbons. Adams explains, “Used oils are oxidized, often containing acidic compounds in addition to metals like zinc and antimony as well as biocides or other toxic components that are present in the used oils.” Additionally, Adams says, each used oil requires the addition of new components to make up for any depletion that cannot be removed by re-refining. The result? “Re-refined mineral oils can be used to successfully formulate standard mineral oil-based lubricants; however, these lubricants could not be classified as EALs,” says Adams.

Read More

Singapore, RSC Bio Has You Covered

June 22, 2021

Please join us in welcoming Wing Hau CHIA to our Global Marine team in the position of Business Development Manager covering Singapore and APAC beyond. Wing Hau brings more than 12 years marine experience with ABB Marine, General Electric Power Conversion, Trafotek Marine Power Conversion and Damen Shipyard Gorinchem, Wing Hau has the technical and commercial expertise to help operators successfully incorporate FUTERRA™ and EnviroLogic® EALs into fleets and equipment.

Pile Buck & RSC Bio on Best-in-Class Oil Monitoring and Analysis Programs

June 22, 2021

Many factors come into play when you are evaluating lubricant options for your fleet. These factors include original equipment manufacturers’ recommendations and approvals, quality, intended application or use, operating conditions, required performance, oil life and price. But there is another very important factor that is often overlooked — how to evaluate lubricant effectiveness once it’s in use.

Pile Buck and RSC Bio take a deep dive into the importance of an oil analysis program and highlight best practices you can apply as you establish your program. If you already have an oil analysis program in place, these best practices are a great benchmark to ensure your program is primed for success.

The feature article begins on page 74.

Read More

Marine Propulsion: Lubricant Selection, Performance, and Monitoring Best Practices

March 11, 2021

Read More

Pile Buck Vol 37, Issue 1: The Impact of Water in Hydraulic Systems

March 4, 2021

Read More

A New Accelerant + Macro Trends Impacting Sustainable Technology Adoption

February 8, 2021

By Mike Guggenheimer, President & CEO

Since RSC Bio Solutions sits on the leading edge with sustainable technologies and solutions, I am often asked for my view of whether the trend is accelerating and by how much. In a recent conversation with a fellow leader looking at macro trends on this topic, I found myself landing on a clear view which until recently was more opaque. I will preface this as my perspective, and I would welcome the opportunity to compare notes, discuss and share more about what is happening.

Essentially, there are a handful of factors that are causing the move towards green tech – which have been developing slowly for years – to pick up steam. . . and one new twist that I believe is adding the most horsepower to the trend and really starting to change the pace of change.

For much of our nearly 40 years in this space, the use of sustainable and green solutions was limited to a niche of lead users and early adopters. Initial industry solutions (e.g., early bio lubricants) were very expensive and performed poorly, so companies would only adopt them when regulated. But over the last decade the following trends have transitioned the niche into a viable segment, which is growing faster than the rest of the market:

- Technological improvements – green tech that works – sometimes better than – conventional counterparts.

- Experience curve, new materials, and economies of scale bringing costs down.

- Increasing regulations, globally.

- Increasing incentives, savings, and other rewards for adopting green tech

- Social media and speed of global communication increasing the risk associated with a negative environmental event or exposure.

- More prominent corporate sustainability goals and objectives are an integral part of long-term strategy and a tool to impact internal culture and talent acquisition as well as company financial performance.

There are other factors for sure, but these have been the top factors from RSC Bio’s perspective. They are continuing to gain momentum as more companies we work with are driven by these issues.

So, what is the new factor starting to dwarf the 6 above? The investor community. The most notable example is BlackRock, an investor controlling around $9 trillion. The largest and arguably the most influential investor in the world. For the second year in a row, BlackRock CEO Larry Fink, in his annual letter has made the argument that a focus on sustainability goals will be a defining factor in companies’ long-term prospects because “the creation of sustainable index investments has enabled a massive acceleration of capital towards companies better prepared to address climate risk.” He is not saying that BlackRock wants to invest in companies that focus on sustainability because it is the right thing today—he is saying those companies are the better bet in the long run and this factor will lead to a “fundamental reshaping of finance”. Companies focusing on sustainability goals are already outperforming their peers and the world’s largest investor expects that to accelerate.

So, yes, there are several factors I see supporting the adoption of green tech such as continuous improvement in performance and cost, as well as increasing regulations and incentives. But, with an increasing awareness that green (environmental) technology, as part of an overall approach to sustainability, leads to superior long term financial performance, the adoption curve is going to rapidly accelerate in the years ahead. Companies that fail to recognize this, will be left in the dust.

New Distribution Partner – KSH – Serving South Korea

February 1, 2021

Announcing RSC Bio’s newest EnviroLogic® and Futerra™ lubricants distribution partner based in Hwaseong, South Korea for Marine and Industrial applications in South Korea.

KSH serves many industries and market including:

-

-

- Deep Water Marine – container, bulker, tanker, RORO, passenger, military, Oil&Gas vessels

- Inland marine – river and dredging vessels

- Shipbuilding and Repairs – new vessel construction, repairs, capability enhancements

- Industrial – heavy equipment, hydropower, waterworks, agriculture, public works, military, railroads.

-

Welcome to the RSC Bio Solutions team, KSH!

Pile Buck Vol 36, Issue 6: Choosing the Right EAL for Your Application

January 27, 2021

Read More

LUBES’N’GREASES: Mandated Marine Lubes Vary Widely

January 25, 2021

Government requirements for environmentally acceptable lubricants are relatively simple, but performance properties of products available to the shipping industry can vary widely, according to speakers at a recent online event.

Speakers from several suppliers of biobased base oils and lubricants market shared insights during Marine Maritime Media’s Nov. 23 webinar, “Bio-lubricants for marine vessels and auxiliary equipment: a better return on investment.” They advised ship operators to understand the lubrication needs of their equipment as well as the chemical and performance properties of products on the market before making their selections.

The U.S. Vessel General Permit policy regulates discharges caused by normal operations of commercial vessels in U.S. territorial waters and the Great Lakes. It includes specific requirements for products used to lubricate stern tubes and other equipment that may be immersed in seawater or that may otherwise come in to direct contact with it, referred to as oil-to-water or oil-to-sea interfaces. Commercial vessels longer than 79 feet must use environmentally acceptable lubricants in all oil-to-sea interfaces, such as controllable pitch propellers, azimuth thrusters and paddle wheel propulsion systems. The U.S. Environmental Protection Agency defined these lubes as biodegradable and minimally-toxic and as not bio-accumulative.

Kevin Duncan, market applications specialist – energy technologies for Croda Europe, noted that environmentally acceptable lubricants are a viable and effective option for lubrication, but he added that it is important to understand the differences between different products. Key ISO classifications include hydraulic environmental triglycerides, hydraulic environmental ester oil synthetic, polyakylene glycol base such as polyglycol, and hydraulic environmental polyalphaolefin and related products.

Key factors such as oxidation stability and hydrolytic stability can vary between each classification, and within different producers under each classification. These differences underscore the importance of careful selection, he said. Oxidation stability and hydrolytic stability help slow oil degradation. Another desired effect of the oil, film forming behavior, helps eliminate engineering issues. Together, these help minimize the risk of equipment failure, Duncan said.

Ian Nielsen, strategic account representative for RSC Bio Solutions, noted that each type of hydraulic fluid is characterized by the chemical composition of its base oil. For example, those made with triglyceride base oil offer superior lubricity but rank lower in resistance to oxidation and water. Those made with PAOs and synthetic hydrocarbons offer the strongest oxidation and water resistances, superior lubricity and broad seal compatibility.

Don Gregory, technical director for Gulf Oil Marine, said biobased lubricants may be more sustainable, and they meet requirements because they are biodegradable, non-toxic and not bio-accumulative. Their high polarity makes them excellent lubricants, he noted, and they typically offer a high viscosity index. He emphasized that when considering a changeover in stern tube lubricants, it is important to check suitability of the formulation for the application and to check the compatibility with the previous lubricant. Draining – and if possible purging or manually cleaning – the system is important, he said, to remove all residues of the previous lubricant. It’s also important to change lubricant filters prior to refilling and to ensure any potential sources of external contaminants are eliminated, Gregory said.

Read More

Maritime Reporter: RSC Bio Grows Its Team and Distribution

January 20, 2021

RSC Bio Solutions announced team expansions in several key geographic areas, as well as expanded distribution coverage. Hideki Tominga and Alhareth Shahen are joining as business development managers, Thomas TO is joining as a Technical Business Consultant, and Miranda Lo and Cherl Minot are coming on board in customer support functions. David Simpson has been promoted to lead global business development activities for the marine and offshore division.

“We are proud to be playing a leadership role in developing innovative solutions to address the accelerating challenges heavy equipment and maritime operators face today,” said Mike Guggenheimer, President and CEO of RSC Bio Solutions. “As we respond to growing demand, we are expanding our team in key regions with an extremely talented group that brings deep technical and market knowledge, which is essential to our business model.”

As part of the overall expansion effort, RSC Bio Solutions is increasing its distribution and supply chain coverage in EMEA and APAC. The business had relied on a single global marine distribution and sales partner but recently shifted its strategy to team with strong regional distributor partners, increase its own stock levels in key hubs, and dramatically advance its overall technical support capabilities direct with end users to better meet the accelerating demand.

“Over nearly four decades of experience delivering PAO and synthetic hydrocarbon related technologies, we have developed a reputation for technical and product expertise,” Guggenheimer said. “We have found a sweet spot between ensuring we have extremely high levels of technical and delivery service while maintaining a direct connection with the users of our technology. Our partners increasingly are relying on RSC Bio Solutions personnel to develop strategic roadmaps to mitigate risk and plan for a future where sustainability is no longer optional.”

Thomas Ka-Lok TO is based in Hong Kong and brings over 30 years of tribology and engineering experience, including significant depth in marine lubricant technologies with ExxonMobil, Gulf Oil Marine, Unimarine and Hyundai Oilbank. As a Technical Business Consultant, he will provide technical support to our customers in the APAC region and play a key role on both R&D projects and OEM relationships globally.

Miranda Lo is also based in Hong Kong and as an Account Executive will directly support our customers there, while assisting the RSC Bio Solutions global supply chain and customer service team with oversight of operational activity in APAC. She brings over 15 years of experience in Marine and Oil and Gas segments with responsibilities ranging from sales to customer service and supply chain management with Gulf Oil Marine and TOTAL.

Hideki Tominaga is based in Japan and will be responsible for all commercial relationships in Japan. He brings over 35 years of experience in commercial roles associated with highly technical products, including elastomers, lubricants, additives, and other specialty chemicals in industrial, automotive, and marine markets. Over 25 years of his career was with ExxonMobil and most recently Tominaga led sales and market planning for a leading marine distributor of technical chemical products.

Alhareth Shahen is based in Hamburg and will be responsible for marine and offshore business development in EMEA. Shahen has over 10 years of maritime experience with a strong technical background with a BS in Marine Engineering and Naval Architecture. Most recently he worked with Wilhelmsen Ships Service, as a technical sales leader responsible for the lubricant product line.

Cherl Minott joins the team in the Charlotte headquarters location, expanding RSC Bio Solutions customer solutions capacity. She brings over 5 years of experience in customer service roles with a degree in communications.

David Simpson joined RSC Bio Solutions in early 2020, bringing extensive experience in offshore and marine segments with nearly 20 years of experience in operations, maintenance, and project management with the Royal Navy and a leading jack-up and wind installation vessel operator. In late 2020 he was promoted to Business Development Director to lead the growing Marine team and business.

Read More

RSC Bio Solutions Announces Marine Business Development and Distribution Team Regional Expansions to Meet Growing Global Demand for its Lubricants

January 19, 2021

RSC Bio Solutions is as leading green technology company, helping global marine and industrial fleets prepare for the future with advanced, sustainable solutions that refuse to sacrifice performance.

INDIAN TRAIL, NC, USA – To meet the growing demand for its offerings around the world, RSC Bio Solutions is excited to announce team expansions in several key geographic areas, as well as expanded distribution coverage. Hideki Tominga and Alhareth Shahen are joining as business development managers, Thomas TO is joining as a Technical Business Consultant, and Miranda Lo and Cherl Minot are coming on board in customer support functions. David Simpson has been promoted to lead global business development activities for the marine and offshore division.

“We are proud to be playing a leadership role in developing innovative solutions to address the accelerating challenges heavy equipment and maritime operators face today,” said Mike Guggenheimer, President and CEO of RSC Bio Solutions. “As we respond to growing demand, we are expanding our team in key regions with an extremely talented group that brings deep technical and market knowledge, which is essential to our business model.”

As part of the overall expansion effort, RSC Bio Solutions is significantly increasing its distribution and supply chain coverage in EMEA and APAC. The business had relied on a single global marine distribution and sales partner but recently shifted its strategy to team with strong regional distributor partners, increase its own stock levels in key hubs, and dramatically advance its overall technical support capabilities direct with end users to better meet the accelerating demand.

“Over nearly four (4) decades of experience delivering PAO and synthetic hydrocarbon related technologies, we have developed a reputation for technical and product expertise,” said Mr. Guggenheimer. “We have found a sweet spot between ensuring we have extremely high levels of technical and delivery service while maintaining a direct connection with the users of our technology. Our partners increasingly are relying on RSC Bio Solutions personnel to develop strategic roadmaps to mitigate risk and plan for a future where sustainability is no longer optional.”

Thomas Ka-Lok TO – Mr. TO is based in Hong Kong and brings over 30 years of tribology and engineering experience, including significant depth in marine lubricant technologies with ExxonMobil, Gulf Oil Marine, Unimarine and Hyundai Oilbank. As a Technical Business Consultant, he will provide technical support to our customers in the APAC region and play a key role on both R&D projects and OEM relationships globally.

Miranda Lo – Ms. Lo is also based in Hong Kong and as an Account Executive will directly support our customers there, while assisting the RSC Bio Solutions global supply chain and customer service team with oversight of operational activity in APAC. She brings over 15 years of experience in Marine and Oil and Gas segments with responsibilities ranging from sales to customer service and supply chain management with Gulf Oil Marine and TOTAL.

Hideki Tominaga – Mr. Tominaga is based in Japan and will be responsible for all commercial relationships in Japan. He brings over 35 years of experience in commercial roles associated with highly technical products, including elastomers, lubricants, additives, and other specialty chemicals in industrial, automotive, and marine markets. Over 25 years of his career was with ExxonMobil and most recently Mr. Tominaga led sales and market planning for a leading marine distributor of technical chemical products.

Alhareth Shahen – Mr. Shahen is based in Hamburg and will be responsible for marine and offshore business development in EMEA. Mr. Shahen has over 10 years of maritime experience with a strong technical background with a BS in Marine Engineering and Naval Architecture. Most recently he worked with Wilhelmsen Ships Service, as a technical sales leader responsible for the lubricant product line.

Cherl Minott – Ms. Minott joins the team in the Charlotte headquarters location, expanding RSC Bio Solutions customer solutions capacity. She brings over 5 years of experience in customer service roles with a degree in communications.

David Simpson – Mr. Simpson joined RSC Bio Solutions in early 2020, bringing extensive experience in offshore and marine segments with nearly 20 years of experience in operations, maintenance, and project management with the Royal Navy and a leading jack-up and wind installation vessel operator. In late 2020 he was promoted to Business Development Director to lead the growing Marine team and business.

About RSC Bio Solutions

RSC Bio Solutions is a portfolio company of Blumenthal Holdings and a global leader in sustainable technology for marine and industrial markets with four decades of experience in the most demanding applications. The company is committed to helping global operators reduce environmental risk, increase uptime, and chart a path to a more sustainable future with technologies that rival the performance and compatibility of the best petroleum-based products. For more information visit our website www.rscbio.com or to learn more about our latest project to help businesses keep employees and customer safer, visit www.clean-safely.com.

Riviera Media: Bio-lubricants and the benefits of advanced engineering

January 13, 2021

Bio-lubricants can offer more advanced lubricant technology than petroleum-derived alternatives, according to experts speaking at Riviera’s Bio-lubricants for marine vessels and auxiliary equipment: a better return on investment webinar. Read the highlights here or access the webinar via our Events listing.

Read More

STLE: Biolubricants definitions, key applications and prospects for growth

November 30, 2020

RSC Bio’s VP of Technology, Dr. Larry Beaver, was recently interviewed by STLE on market outlook for biolubricants along with key criteria and applications for these advanced technology, more sustainable alternatives to mineral oil-based lubricants.

Read More

Equipment and Contracting on Pumpable Greases for Environmentally Sensitive Applications

November 30, 2020

Demand for EALs that can be sprayed or pumped long distances onto metal surfaces to reduce friction and provide corrosion protection is strong. The likelihood of softer grades of greases entering the environment are greater since most greases that are NLGI 0 or NLGI 00 grades solubilize and wash off at the point of lubrication.

Read More

NEW! EnviroLogic® Greases 0, 00 WREP – Pumpable Greases for Environmentally Sensitive Applications

November 24, 2020

EnviroLogic® Greases 0, 00 WREP

Pumpable Greases for use in Environmentally Sensitive Applications

By Douglas Adams, Senior Product Development Chemist

The United Nations Decade of Ocean Science for Sustainable Development begins next year. As we approach 2021, the need for high performance EALs for the Marine and Offshore markets has increased and RSC Bio Solutions has products to meet and exceed what’s required for these applications.

Demand for EALs that can be sprayed or pumped long distances onto metal surfaces to reduce friction and provide corrosion protection is strong. The likelihood of softer grades of greases entering the environment are greater since most greases that are NLGI 0 or NLGI 00 grades solubilize and wash off at the point of lubrication.

The EnviroLogic® WREP family of greases are VGP compliant and possess a high degree of film strength that enables adherence to steel surfaces. The film strength is best illustrated with the Salt Fog test which measures protection of a steel panel (ASTM B 117) with an application of EnviroLogic® 00 WREP. The steel panel coated with this grease did not develop any corrosion in the test area after 1,500 hours. Most NLGI 0, 00 grade greases made with mineral oil fail the Salt Fog test in less than 20 hours.

EnviroLogic 0, 00 WREP greases flow readily at room temperature and maintain their ability to lubricate as demonstrated by their exceptionally low Four Ball Wear results of 0.40 mm or less.

The thin film of these greases prevents corrosion, provides extreme pressure and anti-wear protection to steel surfaces when being pumped in a centralized system for long distances in an application like RORO (Roll On Roll Off) latches on ships.

High quality Environmentally Acceptable Greases like the EnviroLogic® WREP 0 and WREP 00 greases can also be sprayed under pressure onto wire ropes, rail switch plates and can be applied using most air pressurized applicators.

Splash 24/7 on Choosing the Right EAL

November 22, 2020

The editors at Splash 24/7 highlighted RSC Bio Solutions for it’s leadership in helping to educate Marine operators on how to select the right EAL for the job.

Read More

Pile Buck on New EnviroLogic WREP 1 Grease

November 22, 2020

This newly introduced grease outperforms other wire rope and jack up leg greases in the market and is also compatible with automated wire rope cleaning and lubrication systems such as Viper.

Read More

New! EnviroLogic® Multi-Purpose Grease 2

November 17, 2020

By Douglas Adams, Senior Product Development Chemist

There is a growing emphasis on the use of high performance, Environmentally Acceptable Lubricants (EALs) that align well to sustainability strategies of companies which reduce operating and reputational risks including industrial and mining applications.

EnviroLogic® Multi-Purpose Grease 2 is a cost effective, versatile, biodegradable lubricant that can be used in many applications to reduce wear and friction. This lubricant will seal out contaminants like water and debris in chassis and general-purpose applications.

Too often greases that qualify as EALs must be re-applied frequently to perform like mineral oil-based greases. Some of the reason that frequent reapplication is required are:

Unstable thickener formation – Some base oils do not effectively solubilize the thickener, which causes excessive oil bleed and grease softening.

Minimal amounts of extreme pressure and anti-wear additives in the formulation to reduce cost and meet EAL requirements will not durably protect the equipment to which it is applied.

Many EAL greases are not formulated with effective polymers, and consequently do not withstand direct water spray resulting in wash off.

EnviroLogic® Multi-Purpose Grease 2 is an Extreme Pressure grease designed to replace mineral oil-based greases that can be used in similar applications and reduce wear and friction.

This lithium complex grease is well suited to high humidity environments due to the polymers, steel and copper corrosion inhibitors included in our formula to provide a barrier to corrosion that will extend the life of the equipment that it is applied. Additionally, it is compatible with most greases in the market, so changeover is easier.

At RSC Bio, we understand the performance demanded in industrial and mining applications and have designed our grease products to deliver performance without environmental tradeoffs. Let us help you Solve Smarter.

NEW EnviroLogic® Grease 1 WREP Applications in Wind Turbine Installation and Service

November 11, 2020

by Douglas Adams, Senior Product Development Chemist

Wind Turbines are a renewable and sustainable alternative for electricity generation and the use of high performance, Environmentally Acceptable Lubricants (EALs) in installation and maintenance of wind turbines aligns well to the overall sustainability mission. Let’s review applications for EnviroLogic Grease 1 WREP (water resistant, extreme pressure high performance) and why it is a better choice than commonly used coatings on the market today.

Jack Up Legs

Jack Up boats are effective in shallow water to stabilize the vessel while the Wind turbine components are hoisted into position during the installation process and servicing. During normal operation of a Jack Up boat, three Jack Up legs are raised or lowered in the water to stabilize the vessel during which time EnviroLogic Grease 1 WREP is self-applied from stationary rings surrounding each leg to lubricate and protect the legs from corrosion and excessive wear.

Wire Ropes

The cranes that are used to hoist the parts from the Jack Up boat during installation and service of wind turbines most often utilize steel wire ropes. The maintenance of wire ropes in marine environments has long been a difficult task due to the need for the lubricant to penetrate the outer and inner wire strands, provide extreme pressure protection and prevent corrosion.

The EnviroLogic Grease WREP family of greases has been thoroughly evaluated in terms of steel corrosion with ASTM B 117 Salt Fog test and no corrosion was detected in the test area after 1,000 hours. EnviroLogic WREP family of greases has been used on wire ropes effectively for over three years with only positive feedback.

To safely ensure optimal lubrication of wire rope, the first step is to clean the cable before introducing a flowable lubricant which can penetrate beyond outer strands through to the inner strands of the wire rope.

VIPER Wire Rope Cleaning and Lubrication System

RSC Bio Solutions has teamed with Viper to offer our customers a wire rope cleaning and lubrication system proven to consistently provide lubrication to both the outer and inner strands of wire in the wire rope and extend wire rope life significantly.

The Viper system was developed specifically for wire rope applications; first it removes any debris that accumulates on used wire rope and then, as the cable passes through the Viper System, EnviroLogic Grease 1 WREP is applied under air pressure into and onto the wire rope penetrating enabling penetration beyond outer strands.

EnviroLogic Grease 1 WREP was engineered specifically to flow at lower temperatures and penetrate wire ropes more consistently. Its adhesive characteristics enable EnviroLogic Grease 1 WREP to remain on the cable longer, retain its flexibility as a lubricant and offers 400 kgf Four Ball Weld that reduces the friction between the steel wires.

Many of the products offered for wire ropes are not lubricants at all – offering little to no extreme pressure protection and frequently cracking under flex. To learn more about EnviroLogic Grease1 WREP and Viper lubrication systems or how it compares to your current coating product, contact RSC Bio technical representatives to help your company Solve Smarter.

Basic Chemistry Principles Will Make Cleaning Your Home Easier

October 29, 2020

You don’t need to know how to balance a chemical equation (remember that?), but understanding some science jargon can help. Read more from experts interviewed including Dr. Larry Beaver, VP R&D at RSC Bio Solutions.

Read More

Maritime CEO Profiles Mike Guggenheimer, RSC Bio CEO

October 22, 2020

“At its core, Bio is about proving to the world that great biotechnology delivers a financial business case for using sustainable technology,” says Mike Guggenheimer, the company’s CEO.

Read More

We Have You Covered

October 21, 2020

by Scott Sickmiller,

Vice President, Operations

One late afternoon recently, our sales representative fielded a call from a global marine operator who had a vessel headed to Asia Pacific with a stern tube system issue urgently necessitating the need for new lubricant. The system issue was reportedly due to use of a HEES (hydraulic fluid environmental synthetic ester) lubricant from an oil major that didn’t stand up to the performance demanded and support wasn’t readily available from the HEES fluid supplier.

Our sales rep, working in concert with RSC Technical Service and Operations teams in Cleveland, Ohio, and Charlotte, NC, was able quickly confirm the necessary stern tube and seal OEM approvals, ship the critically needed 8 drums of Futerra™ Hydraulic Fluid 100 iso grade product to deliver port side within 10 hours of the first call from the operator. We are now assisting the operator with routine sampling, monitoring and analysis of the Futerra lubricant to provided added peace of mind.

In addition to offering only advanced performance, environmentally acceptable lubricants, RSC Bio Solutions offers best in class service, support and the most comprehensive OEM approval set in the Environmentally Acceptable Lubricants category.

Please get in touch with the team at sales@rscbio.com if you would like to learn more about EALs, the effects of water on many types of lubricants and equipment, or oil monitoring and analysis services.

American Bureau of Shipping Adds Thymox to Covid 19 Response Measures

October 8, 2020

The American Bureau of Shipping just added Thymox – the active ingredient in RSC Bio’s Bioesque Disinfectant Solution (https://rscbio.com/blog/product/bioesque-disinfectants/) – to the October update of its Guidance Notes for Response Measures for Covid 19 for the Marine and Offshore Industries. Let the experienced Marine team at RSC Bio Solutions help you protect your biggest asset – your employees – and keep your Operations moving forward.

Pile Buck / EnviroLogic WREP 2 Grease

September 15, 2020

The latest of edition of PileBuck (Volume 36, Issue 4 2020) spotlights EnviroLogic WREP 2 grease and its formulator, Doug Adams, on page 142.

Read More

BUSINESSES CAN CLEAN WITH CONFIDENCE WITH NEW CLEAN SAFELY PLATFORM POWERED BY RSC BIO SOLUTIONS

June 17, 2020

INDIAN TRAIL, NC – The new Clean Safely platform powered by RSC Bio Solutions launched today, providing curated solutions that meet the escalating challenge to safely eliminate viral threats in public, commercial, and industrial spaces. A legacy company with 30 years of experience in the high-performance sustainable space for both marine and land applications, RSC Bio Solutions has a successful history of developing environmentally-friendly products for diverse industry applications.

Clean Safely offers businesses a future-proof protocol to clean with confidence. RSC Bio Solutions designed Clean Safely as a holistic solution to simplify what has recently posed a complex challenge for multiple industry sectors, including manufacturing and distribution, transportation, governments and municipalities, and healthcare, senior and childcare facilities. By focusing the three pillars of cleaning, disinfecting and maintaining, the protocol breaks down these processes into easy-to-manage steps, supported by high-performance products.

“There is so much noise and confusion surrounding how to clean and disinfect public premises that we decided to turn our in-depth industry knowledge into curating simple, clear-cut solutions,” said Mike Guggenheimer, RSC Bio Solutions’ President and CEO. “We see our role as a trusted advisor with the expertise and products to help businesses and industries prepare spaces to open safely and efficiently, keep operations moving and maintain clean and safe working environments during re-opening and for the future.”

Clean Safely products have been thoroughly vetted by the RSC Bio Solutions research and development team and selected based on their versatility, ease of use and effectiveness. The platform was built for flexibility in order to tailor individualized protocols that meet specific industry requirements pertaining to space, frequency, manpower and equipment.

The first component of Clean Safely always focuses on the essential – but often overlooked – step of deep cleaning surfaces to ensure they are free of the dust, grime and dirt that attract viral and bacterial particles. For example, the protocol’s EnviroLogic CSR-2000 Cleaner is meant for large surface areas and industrial use. For smaller spaces, the company’s widely-recognized GUNK brand Biodegradable General Purpose Cleaner and Degreaser in a ready-to-use trigger spray bottle and GUNK Multi-Purpose Wipes are effective for quick and easy application.

After the overall surface is clean, the next step in Clean Safely is to disinfect the area. The platform features the sanitizer and disinfectant cleaner BIOESQUE, which is unique in the marketplace because it does not require rinsing, even on food contact surfaces. BIOESQUE is registered by the Environmental Protection Agency (EPA) as a Broad-Spectrum Botanical Disinfectant Solution and is also registered in the NSF International Nonfood Compounds Registration Program. It has an efficacy of 99.99 percent sanitation for killing a full range of disease-causing viruses, including Human Coronavirus, in one minute. It provides the same level of sanitation for bacteria, fungi and molds.

“Our best defense against another outbreak is shared knowledge, best-in-class products and the discipline to follow strict industry-appropriate protocol,” said Larry Beaver, Ph.D., Clean Safely Vice President of Research and Development. “As technologists with a long history of performance in environmental technology, we are uniquely qualified to curate this holistic platform and enter the space of safe, healthy and high-performing cleaning and disinfecting solutions.”

Read More

RSC Bio Solutions Partners with TeleSwivel & GSA

May 22, 2020

Here at RSC Bio Solutions, we are excited to share our recent partnership with TeleSwivel – a Service-Disabled Veteran Owned Small Business (SDVOSB) founded in 2009. With this partnership, RSC Bio’s full range of high performance, environmentally preferable lubricants are now available to government customers at the GSA Advantage e-commerce site.

TeleSwivel (TS) works with a select group of manufacturing partners to bring high value solutions to government fleets that enhance safety, help meet sustainment goals, and increase the return on fleet assets. TS sales, marketing, and distribution services deliver value to government fleet managers who may not be aware of TS partners’ technology. TS offers these products to customers at all levels of government through Cooperative Purchasing terms on all products on the Company’s Government Services Administration (GSA) Multiple Award Schedule (MAS) contract.

Read More

EnviroLogic® Grease 2 WREP, A Water Resistant and Environmentally Acceptable Lubricant

May 18, 2020

by Douglas Adams,

Senior Product Development Chemist

I have been formulating finished lubricants, additives, and additive packages for nearly 30 years. When I was assigned the project to develop a high performance, water resistant grease that also had to be an Environmentally Acceptable Lubricant (EAL), it took all my experience and knowledge to accomplish this mission.

First, what is an EAL and how does one locate the raw materials to develop an EAL?

EALs are defined by EPA Vessel General Permit as:

1) biodegradable by 60% or more in 28 days

2) minimally toxic to defined marine species

3) must not bio-accumulate in the fatty tissue of fish.

Raw materials that can be used to formulate EALs are described on the European Ecolabel Lubricant Substance Classification list or LuSC list.

My next step was to formulate the LuSC-listed components into a grease that could deliver best in class performance and remain stable over time.

The grease was designed with marine environments and operating areas that are close to the water in mind, so the grease had to remain on the metal surface when the surface is sprayed with water, submerged in water or water is constantly being reintroduced on to the lubricant and metal surface in the form of mist or fog. Recent technological developments enabled me to address increasing the grease film strength to attain better performance with water.

Most greases in this market had water spray off results of 50% or more resulting in the need for increased re-lubrication frequency to improve corrosion protection. While this has been the industry solution, that work around is expensive for operators.

I then chose a lithium complex grease that had a very good upper operating temperature of 450°F (232°C) as the thickener. Lithium-based greases account for over 75% of the grease market and due to the fact that our grease is a lithium complex type, it is likely to be compatible with lithium-based greases that are currently in use. The benefit for operators using this grease for the first time is that there will be minimal to no changeover or compatibility issues.

Next, using the information from the LuSC list, I developed a base fluid and additives that could meet or exceed other key performance goals.

Many times, film strength is accomplished through the use of thick, viscous materials that do not perform well at low temperatures. I took a different path with EnviroLogic Grease 2 WREP, so it meets industry standards on the Low Temperature Torque Test at -40°C. The Extreme Pressure aspect of this grease is due to the 400 kgf Four Ball Weld result along with the 0.46 mm Four Ball Wear scar. The Timken, OK Load is a 55# Pass.

The result was the development of EnviroLogic Grease 2 WREP (Water Resistant Extreme Pressure) which possesses an industry-leading water spray off performance of 4%. Due to the exceptional film strength of this grease, the ASTM salt fog test ran for over 1,000 hours with no visible corrosion on the cold-rolled steel surface.

RSC Bio offers best in class lubricants and greases like EnviroLogic Grease 2 WREP to protect your equipment in operation or during stacking – helping operators Solve Smarter.

Beyond the Crisis: Emerging Themes to Factor into Business Readiness

May 11, 2020

by Mike Guggenheimer

CEO, RSC Bio Solutions

As responses to contain the COVID-19 crisis continue and phased reopening and recovery begin, there are a few consistent themes emerging within our customer base that I believe will endure beyond the initial responses. Clearly, right now, customers are placing a priority on the immediate demands of disinfecting facilities to prevent or respond to positive cases, providing essential protective gear to front line staff, and building a strategy to safely re-enter buildings after months of working remotely. I am proud of the work our team has completed to rapidly respond to these urgent customer needs. After things start to get back to something that resembles normal, I believe there are a few business readiness factors that are going to move up the priority planning list for the longer term:

Healthy environments – This recent crisis has increased the awareness of how important it will be to maintain not only a safe work environment, but also a healthy one. This means proper protocols for deep cleaning and disinfecting, management of air quality, and efficient tools for maintaining common areas that could be exposed to new threats. It could also be paying more attention to the employee and environmental hazards on products being utilized. This is not only something to keep businesses running smoothly, but also something employees will see as a critical factor in their individual satisfaction and comfort at work.

Supply chain stability – As the COVID-19 crisis began to spread around the world, global supply chains were and still are significantly disrupted. Companies dependent on sourcing raw materials or finished good from areas that were completely shutdown were hit with delays and supply shocks. Companies may rely more on local sources, dual sourcing, or vendors that have strong supply chain networks.

Resiliency and future-ready – Many have been caught off guard by this crisis. To some extent, this was unavoidable, but companies may take a closer look at sources that are sustainable, products that are versatile, and partners that are nimble and responsive.

It is hard to imagine some things not changing permanently from a crisis of this magnitude. I do not know if face masks will become the norm or airplanes will remove the middle seat (I am hoping for that one!), but I am pretty confident we will be looking at things differently for a long time.

Idling Offshore Assets and Equipment with Less Disruption and Cost

May 4, 2020

Idling Offshore Assets and Equipment with Less Disruption and Cost

by Jan Verdaasdonk, Technical Business Consultant, RSC Bio Solutions

The offshore oil and gas industry has been slowly recovering from the last downturn in 2014 that savaged the industry. The current COVID-19 crisis and related decrease in global demand for crude, combined with the lack of cooperation between the major producers to limit production, has resulted in an unprecedented decline in oil prices.

How do operators respond to this crisis? How long is this downturn going to last? What is the best strategy to get through this extremely difficult period? These are all questions that undoubtedly go through the minds of managers working in the offshore industry.

A consequence of low oil prices will be offshore rigs taken out of service at the expiry or cancellation of current contracts. With virtually no new work available, a suitable asset strategy needs to be implemented to weather this storm. There are three scenarios for rigs coming of contract: scrapping, cold stacking and warm stacking.

Scrapping is the most likely scenario for old outdated rigs, with limited remaining economic lifetimes. This scenario will cost the least in the long run, but obviously reduces your number of assets and capabilities long term and will require cash outlay in the short term. With the current closure of many country borders, it can be difficult to secure a scrapping slot at an approved scrapping yard and securing transport from the current operational area to the scrapping location will dependent on availability.

Warm Stacking, the common short-term solution for rigs between jobs, can also be used if the downturn is expected to be short to medium term. The ongoing operational cost of the rig will be higher. In the range of USD$40,000 to 70,000 per day depending on the rig and its location. Class requirements for surveys will continue as per normal.

Cold stacking is used for rigs that are still valuable to keep within the company, but there is no near-term contract available for them. The cost to stack the rig is many millions and the same to re-activate or return to service. The upside is that the daily operational cost goes down significantly to USD$3,000-10,000 per day. To cold stack rigs properly, a lot of preservation work needs to be performed as the rigs are effectively shut down – with the exception of some emergency equipment like firefighting and bilge pumps. Equipment needs to be properly protected against corrosion and seizing, so water-based fluids will be drained and replaced with inhibitors, lubricants need to be checked for longevity and tendency to develop acids over time. Upon re-activation the inhibiters need to be replaced with the correct viscosity fluids and the lubricants need to be tested for operational suitability. Class requirements for survey will be changed depending on stacking methodology and class society.

RSC Bio can help you Solve Smarter with the appropriate choices of lubricants and greases to protect your equipment during stacking in a cost-efficient way, with improved reactivation costs. RSC Bio Solutions products are:

RSC BIO SOLUTIONS IS PARTNERING WITH BIOESQUE®

April 29, 2020